D343H Metal-Seated Butterfly Valve Series

manufacturer: Kaiweixi Valve Group Co., Ltd

Eml: Carrie@kaiweixi.com

Tel: +86 (577) 67038872

Mob: +86 189 6779 6392(WeChat Same Account)

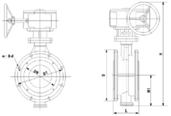

product drawing

D343H Metal-Seated Butterfly Valve Series

Overview

The D343H Metal-Seated Butterfly Valve is a flanged butterfly valve featuring a multi-layer metal hard-seal structure, which achieves tight shutoff through the triple eccentric principle. The valve incorporates a triple-eccentric geometry—axial eccentricity, radial offset, and conical angle eccentricity—allowing the disc to completely disengage from the metal sealing ring during operation, with wedge-type compression sealing only occurring at the final closed position. The valve stem is driven by a worm gear mechanism, enabling smooth operation and providing a self-locking function. The sealing pair consists of a composite laminated structure with stainless steel sheets and flexible graphite, or the disc sealing surface is overlay welded with hard alloy, forming a high-hardness, wear-resistant metal sealing system with the metal seat of the valve body. This design makes the valve suitable for demanding applications involving high temperatures, high pressures, and media containing solid particles.

Features

1、Multi-Layer Metal Hard Seal: The sealing pair adopts an elastic sealing ring formed by alternately laminated stainless steel sheets and flexible graphite, or the disc surface is overlaid with hard alloy, creating multiple sealing barriers. This structure provides excellent wear resistance, high-temperature tolerance, and extended service life.

2、Triple-Eccentric Design: Based on precisely calculated three-dimensional eccentric geometry, the disc completely disengages from the sealing ring at the moment of opening, eliminating friction during rotation. During closing, the eccentric distance enables progressive wedge-type compression, ensuring reliable sealing with low operating torque.

3、High-Temperature and High-Pressure Resistance: The metal sealing structure allows the valve to operate long-term in high-temperature environments up to ≤425°C, with pressure ratings reaching PN16–PN40. It is suitable for industrial media such as steam, thermal oil, and high-temperature flue gas.

4、Erosion and Corrosion Resistance: The hard sealing surfaces effectively withstand erosion and corrosion from solid particles, crystalline substances, or mildly corrosive components in the medium. The valve body interior can be coated with anti-corrosion layers to extend overall service life.

5、Bidirectional Zero-Leakage Sealing: Leveraging the self-energizing effect of the eccentric design, the valve achieves metal hard sealing under both forward and reverse pressures, meeting bidirectional zero-leakage standards. Installation is not restricted by medium flow direction.

6、Long Life with Low Maintenance: The worm gear mechanism ensures smooth and reliable operation, while the hard sealing pair offers exceptional wear resistance. Under normal operating conditions, the valve can function maintenance-free for extended periods, making it particularly suitable for critical processes in industries such as power generation, metallurgy, and chemical processing, where high reliability is essential.

Dimensions & constructral diagram

D343H Metal-Seated Butterfly Valve Series constructral diagram(pic1)

The main technical parameters

| Item | Specification | Unit |

|---|---|---|

| Nominal Pressure | 1.6 | PN |

| Strength Test Pressure | 2.4 | MPa |

| Seal Test Pressure | 1.76 | - |

| Operating Temperature Range | ≤425 | ℃ |

Standard

| Item | Specification | Unit |

|---|---|---|

| Nominal Pressure | 1.6 | PN |

| Strength Test Pressure | 2.4 | MPa |

| Seal Test Pressure | 1.76 | - |

| Operating Temperature Range | ≤425 | ℃ |

The main external and connection dimensions

| Nominal Diameter (DN) | Principal Dimensions | 1.0MPa Flange & Bolt Specifications |

1.6MPa Flange & Bolt Specifications |

2.5MPa Flange & Bolt Specifications |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | H1 | H | D | D1 | n-d | D | D1 | n-d | D | D1 | n-d | |

| 50 | 108 | 350 | 112 | 165 | 125 | 4-18 | 165 | 125 | 4-18 | 165 | 125 | 4-18 |

| 65 | 112 | 370 | 115 | 185 | 145 | 4-18 | 185 | 145 | 4-18 | 185 | 145 | 4-18 |

| 80 | 114 | 380 | 120 | 200 | 160 | 4-18 | 200 | 160 | 8-18 | 200 | 160 | 8-18 |

| 100 | 127 | 420 | 138 | 220 | 180 | 8-18 | 220 | 180 | 8-18 | 235 | 190 | 8-22 |

| 125 | 140 | 460 | 164 | 250 | 210 | 8-18 | 250 | 210 | 8-18 | 270 | 220 | 8-26 |

| 150 | 140 | 550 | 175 | 285 | 240 | 8-22 | 285 | 240 | 8-22 | 300 | 250 | 8-26 |

| 200 | 162 | 765 | 200 | 340 | 295 | 8-22 | 340 | 295 | 12-22 | 360 | 310 | 12-26 |

| 250 | 165 | 830 | 243 | 395 | 350 | 12-22 | 405 | 355 | 12-22 | 425 | 370 | 12-30 |

| 300 | 178 | 895 | 250 | 445 | 400 | 12-22 | 460 | 410 | 12-26 | 485 | 430 | 16-30 |

| 350 | 190 | 950 | 280 | 505 | 460 | 16-22 | 520 | 470 | 16-26 | 555 | 490 | 16-33 |

| 400 | 216 | 1190 | 305 | 565 | 515 | 16-26 | 580 | 525 | 16-30 | 620 | 550 | 16-36 |

| 450 | 222 | 1255 | 336 | 615 | 565 | 20-26 | 630 | 585 | 20-36 | 670 | 600 | 20-36 |

| 500 | 229 | 1305 | 380 | 670 | 620 | 20-26 | 715 | 650 | 20-36 | 740 | 660 | 20-39 |

| 600 | 267 | 1340 | 445 | 780 | 725 | 20-30 | 840 | 770 | 20-36 | 865 | 770 | 20-42 |

| 700 | 292 | 1520 | 480 | 895 | 840 | 24-30 | 910 | 840 | 24-36 | 960 | 875 | 24-42 |

| 800 | 318 | 1710 | 530 | 1015 | 950 | 24-33 | 1025 | 950 | 24-39 | 1085 | 990 | 24-48 |

| 900 | 330 | 1870 | 580 | 1105 | 1050 | 28-33 | 1125 | 1050 | 28-39 | 1185 | 1090 | 28-48 |

| 1000 | 410 | 1960 | 650 | 1230 | 1160 | 28-36 | 1255 | 1170 | 28-42 | 1320 | 1210 | 28-56 |

| 1200 | 470 | 2250 | 760 | 1475 | 1390 | 32-39 | 1485 | 1390 | 32-48 | 1530 | 1420 | 32-56 |

| 1400 | 530 | 2435 | 830 | 1655 | 1580 | 32-42 | 1685 | 1590 | 36-48 | 1755 | 1640 | 36-62 |

| 1600 | 600 | 2780 | 1020 | 1915 | 1820 | 40-48 | 1930 | 1820 | 40-56 | 1975 | 1860 | 40-62 |

| 1800 | 670 | 3020 | 1250 | 2215 | 2020 | 44-48 | 2190 | 2020 | 44-56 | 2204 | 2070 | 44-70 |

| 2000 | 760 | 3270 | 1350 | 2325 | 2230 | 48-48 | 2435 | 2230 | 48-63 | 2425 | 2300 | 48-70 |